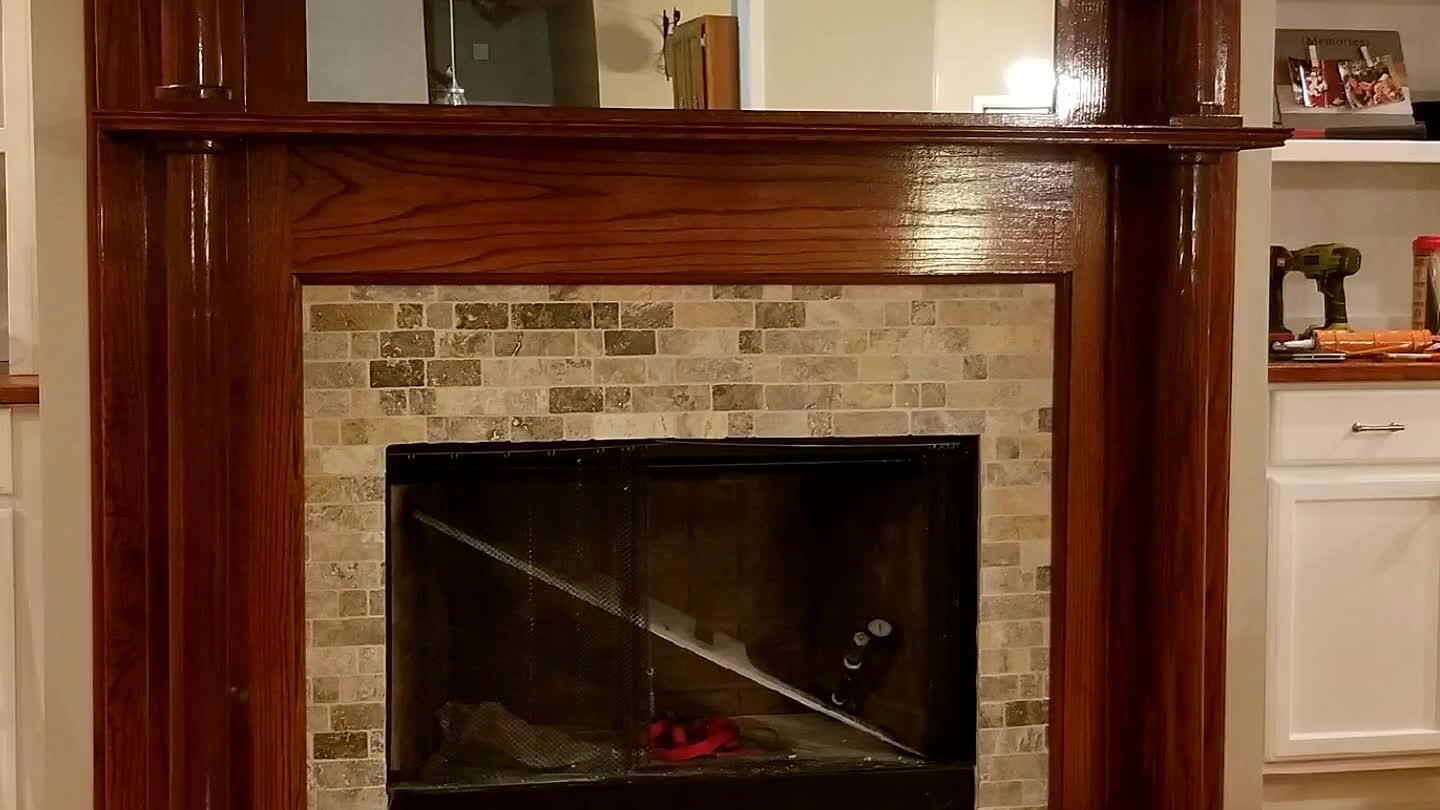

Antique Looking Mantel

Red Oak Mantel

My wife wanted an antique looking mantel for our new addition to our home. She showed me several pictures for inspiration. I think it turned out pretty nice. I had to pay someone with a 5' lathe to turn the posts. I did the rest. Enjoy!

What you will need

You will need the desired wood. In this case red oak.

Mirror (12" x 62")

Hi-temp construction adhesive

16 guage 2.5 finishing nails

2 x 4'x8' General plywood

How to do this project

1

Start with a backer board that meets the needed dimensions. Ensure you check the fire place manufature's recommendations for clearances. You will also need to check your local building codes.

2

Design and cut the various components for the mantel.

3

Test fit each of the components to ensure the dimensions and fit for all of the them are correct. I didn't fasten any of the components to the backer board until I tested them all and a finish had been applied.

4

I took all of the components back to the shop and applied the stain and 3 coats of poly. I also cut the mirror to fit.

5

After I let the last coat of poly dry for at least 24 hours, I took the components in to the house and attached them to the backer board. I used hi temp construction adhesive and 2.5 inch finishing nails. I filled the holes with colored filler.

Comments